Basic Concepts of Applied Thermodynamics

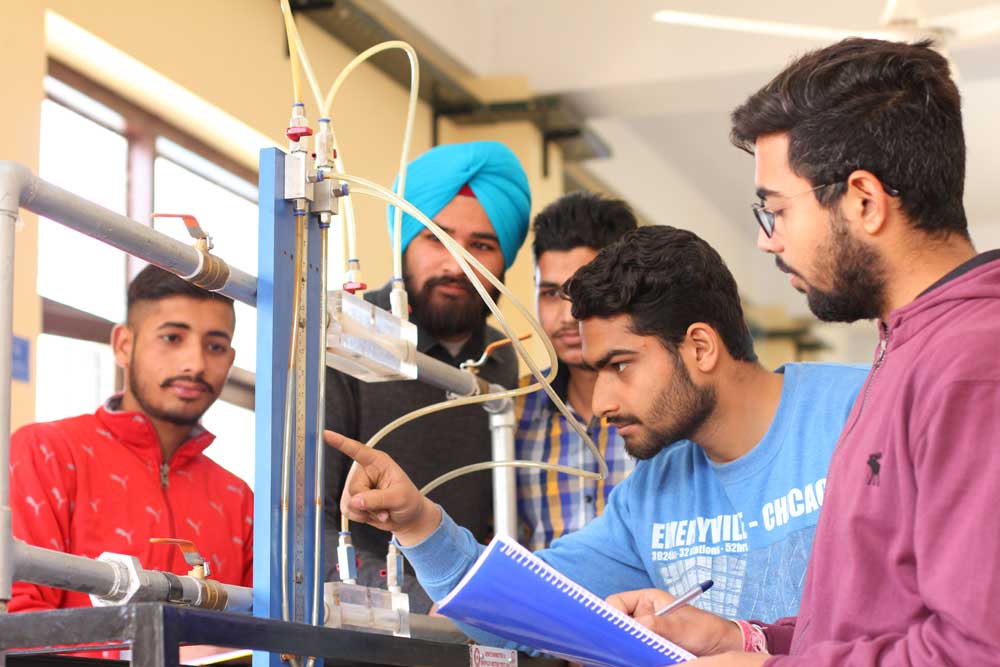

Department of Mechanical Engineering, LKCTC organized an expert lecture on “Basic Concepts of Applied Thermodynamics”. The expert lecture was delivered by Dr. S.K Malha, AP, IKGPTU Hoshiarpur Campus. He primarily emphasized types of boilers, and their practical calculations involving Enthalpy. The process parameters were explained in very interesting ways which are needed for improving the performance of boilers.

The lecture was concluded on a crescendo of applause from students of B Tech (ME), B. Vocational (Automobile Servicing), and Diploma (Mechanical Engg).

Dr. R.S Deol (Deputy Director, Academic Affairs, KCL Group), HOD (ME), and Faculty members of the Mechanical department presented Dr. S.K Malha with a token of appreciation.

S. Sukhbir Singh Chatha (Director, Academic Affairs, KCL Group) and Dr. R.S Deol (Deputy Director, Academic Affairs, KCL Group) appreciated the efforts of department members and encouraged them of arranging more expert lectures in near future for the overall growth of budding Mechanical Engineers.

INDUSTRIAL VISIT TO GNA GEARS MEHTIANA

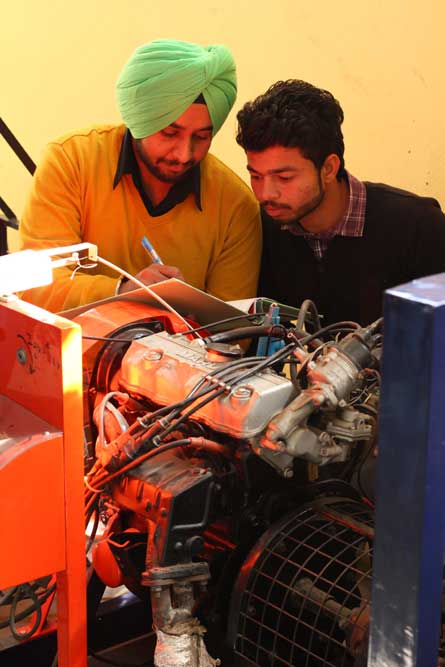

On 06/05/2022, the Department of Mechanical Engineering and T&P Cell organized an Industrial Visit of Diploma (ME) and B.Voc (AS) to GNA GEARS Mehtiana. The purpose of the visit was to enhance the practical & technical skills related to CNC technology, dry machining, and CAM used in the manufacturing industry along with the workflow of the industry. Students get exposure to the actual working of the forging machines, gear cutting machines, broaching, and gear hobbing. Advanced CAM technology was practically explained by the experts Er. Neeraj Mahey and Er. Amit Sharma. Er. Aman Sharma, AP, ME Deptt. and Er.Parvinder Singh, AP , ME Dept. accompanied the students and guided them about their future job prospects in Mechanical Engineering. Dr.Vikas Rattan, HOD, Department of Mechanical Engineering said these types of visits are necessary to aware the students of the latest technology being used by industry.

S. Sukhbir Singh Chatha (Director, Academic Affairs, KCL Group) and Dr. R.S Deol (Deputy Director, Academic Affairs, KCL Group) appreciated the Department of ME & Mr. Arun Dutta, Assistant Director T&P for arranging the Industrial visit. He said that these kinds of industrial visits help the students to understand the actual practical implementation of the concepts which they are studying theoretically. He said that LKCTC is committed to strengthening the academic learning of their students by keeping this practice of arranging industrial visits regularly.

CORPORATE EXPERT TALK by Er. Neeraj Mahey

LKCTC Mechanical Engineering department in association with the Training and Placement cell of LKCTC organized a corporate expert talk on Automation by Er. Neeraj Mahey from GNA Gears Ltd, Hoshiarpur. Keeping in view the academic gap this talk focused on the latest tools of Automation which include the latest design techniques, Simulations of complex geometric shapes. The conversion of a part drawing into a complex computer program and the procedure for the same was neatly explained by Er. Neeraj Mahey. Along with drafting methods, Er. Neeraj Mahey shared his knowledge about 3D printing and job prospects in the same field. The lecture was concluded on a crescendo of applause from students of B Tech (ME) and B. Vocational (Automobile Servicing).

S. Sukhbir Singh Chatha (Director, Academic Affairs, KCL Group) and Dr. R.S Deol (Deputy Director, Academic Affairs, KCL Group) appreciated the efforts of the department and T&P cell for organizing such informative events, wherein the gap between industry and Academics can be bridged.

Industrial visit to Machinex (Machinery- Machine Tools Technology Expo)

Department of Mechanical Engineering in collaboration with the Training and Placement department of LKCTC organized an industrial visit to Machinex (Machinery- Machine Tools Technology Expo) which was held at New Grain Market, Jalandhar City. Students of ME 2nd and 3rd year and B.Voc 1st and 2nd year were part of the visit. Students learned about up-to-date industrial practices involving Automation, Forging, Material Characterization, Modern and Latest tools, and machinery used in the industries. Students learned about the automatic machines which can be used for increasing the production and productivity of the industries. It was indeed a brilliant visit and students learned much about the new technologies used in the industry. S. Sukhbir Singh Chatha (Director, Academic Affairs, KCL Group) and Dr. R.S Deol (Deputy Director, Academic Affairs, KCL Group) appreciated the effort of the department and T&P cell by encouraging more of such visits in near future.

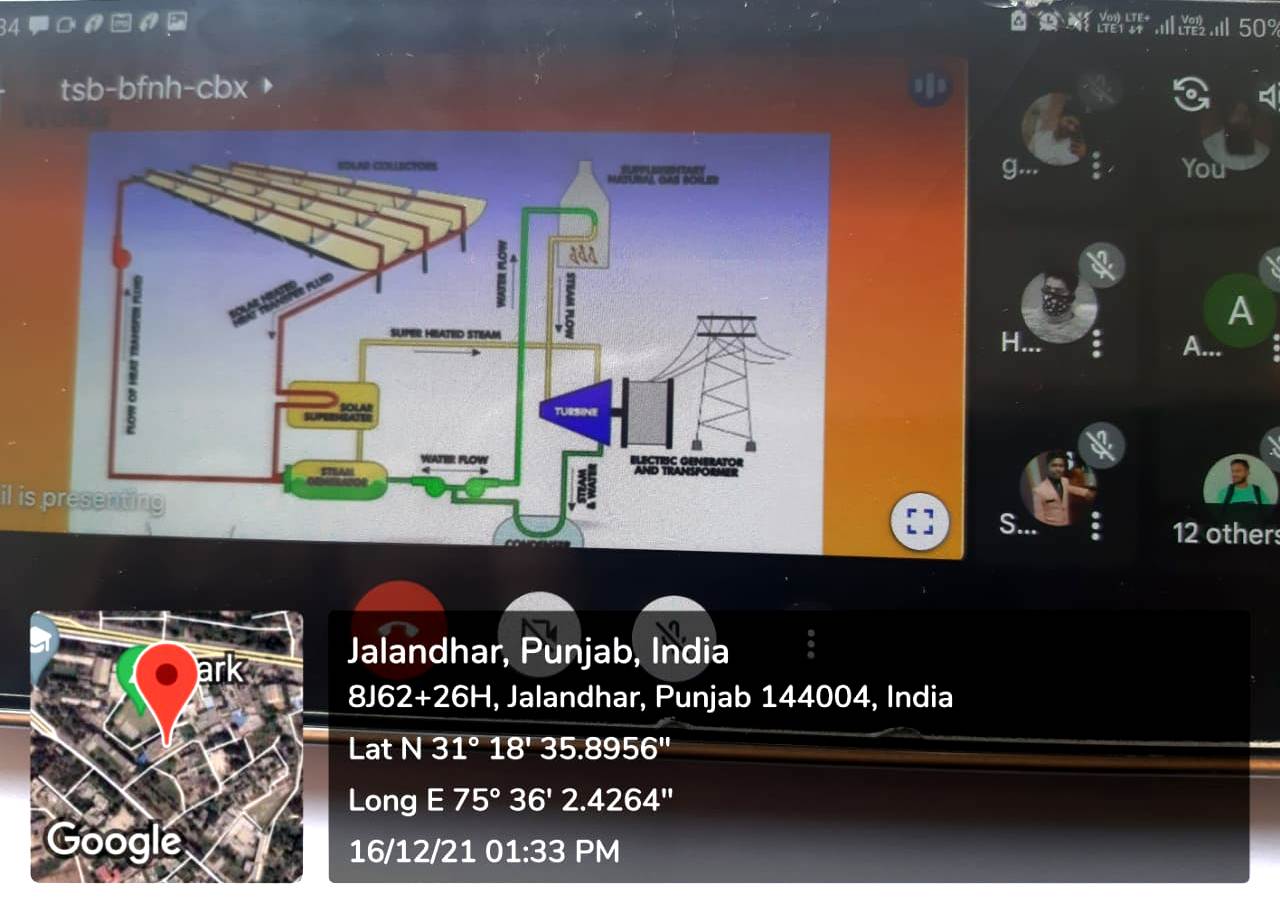

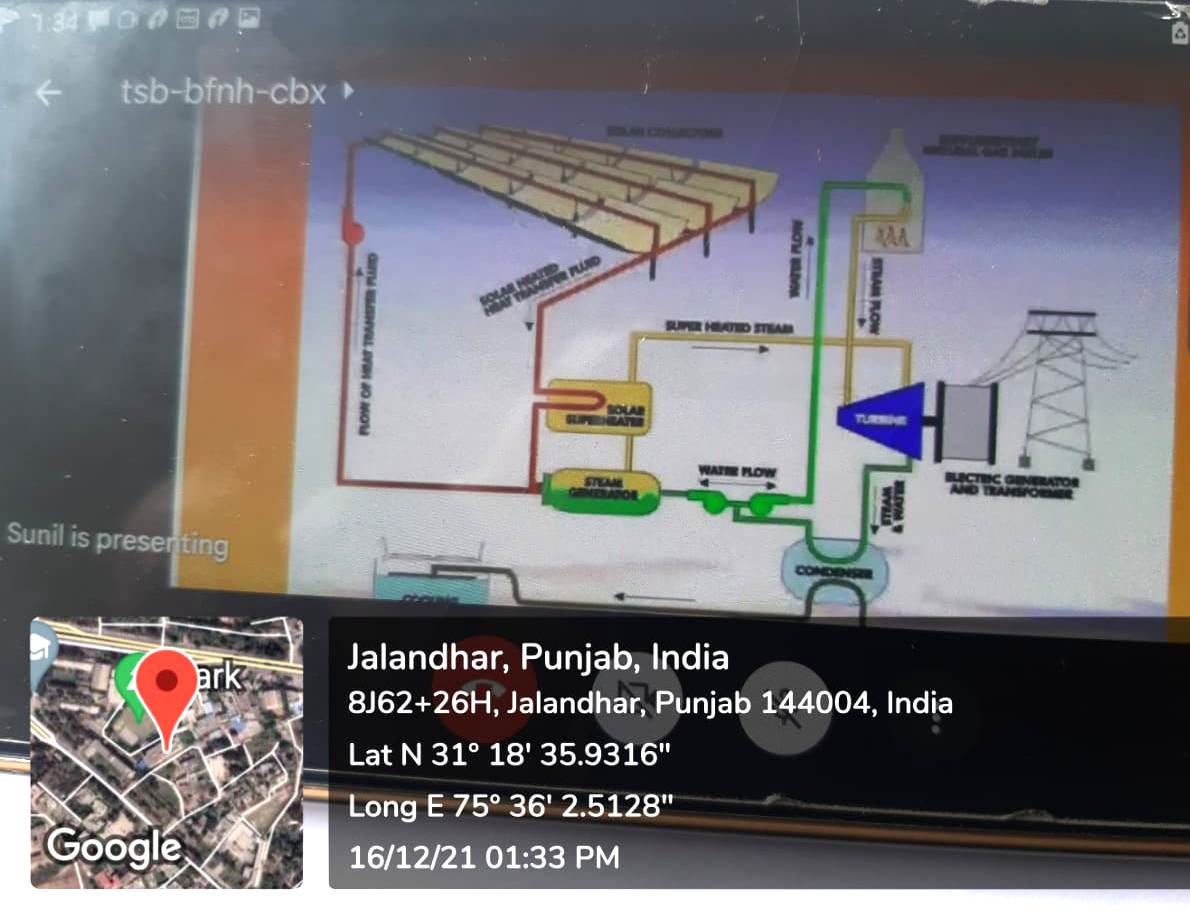

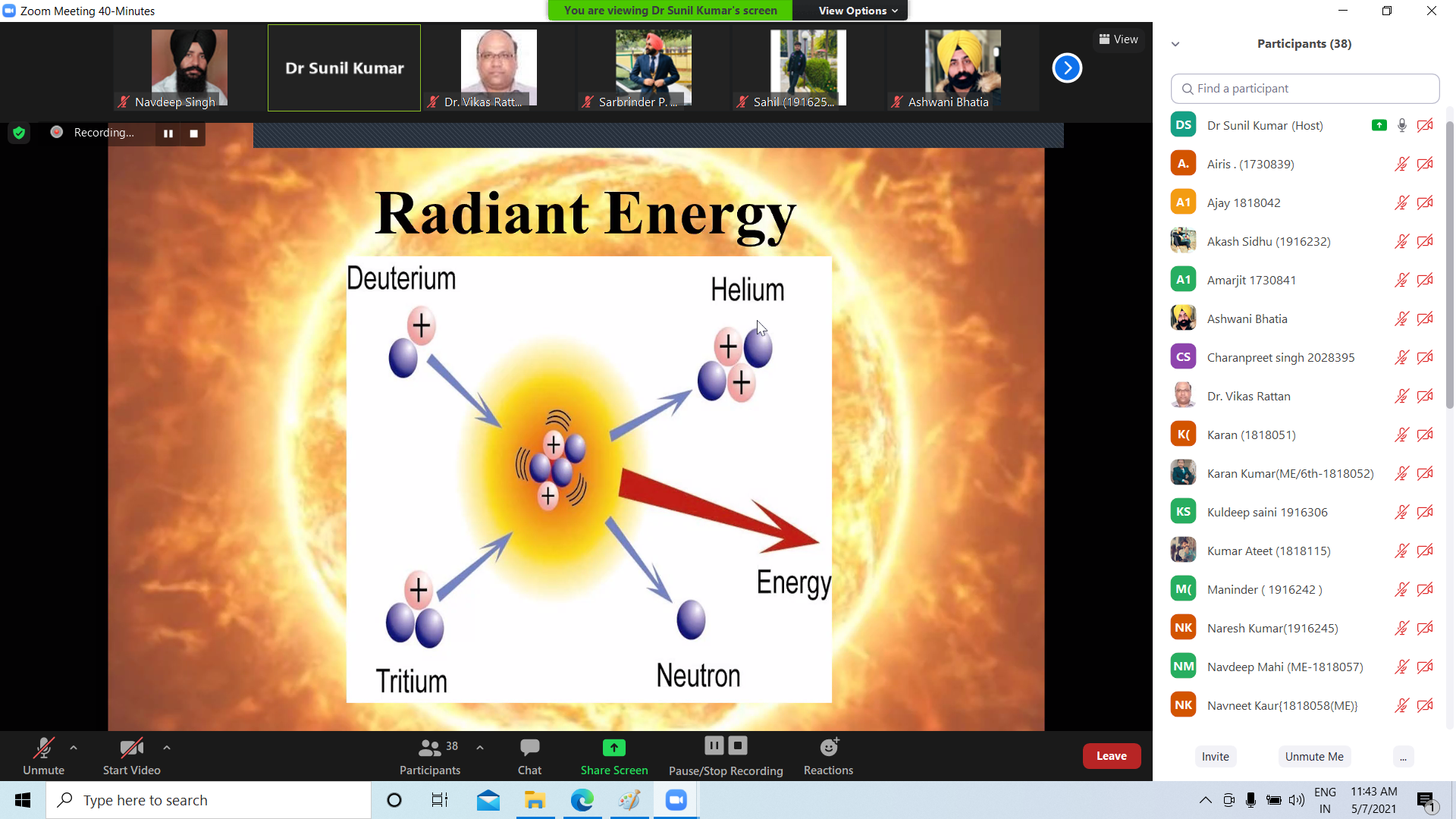

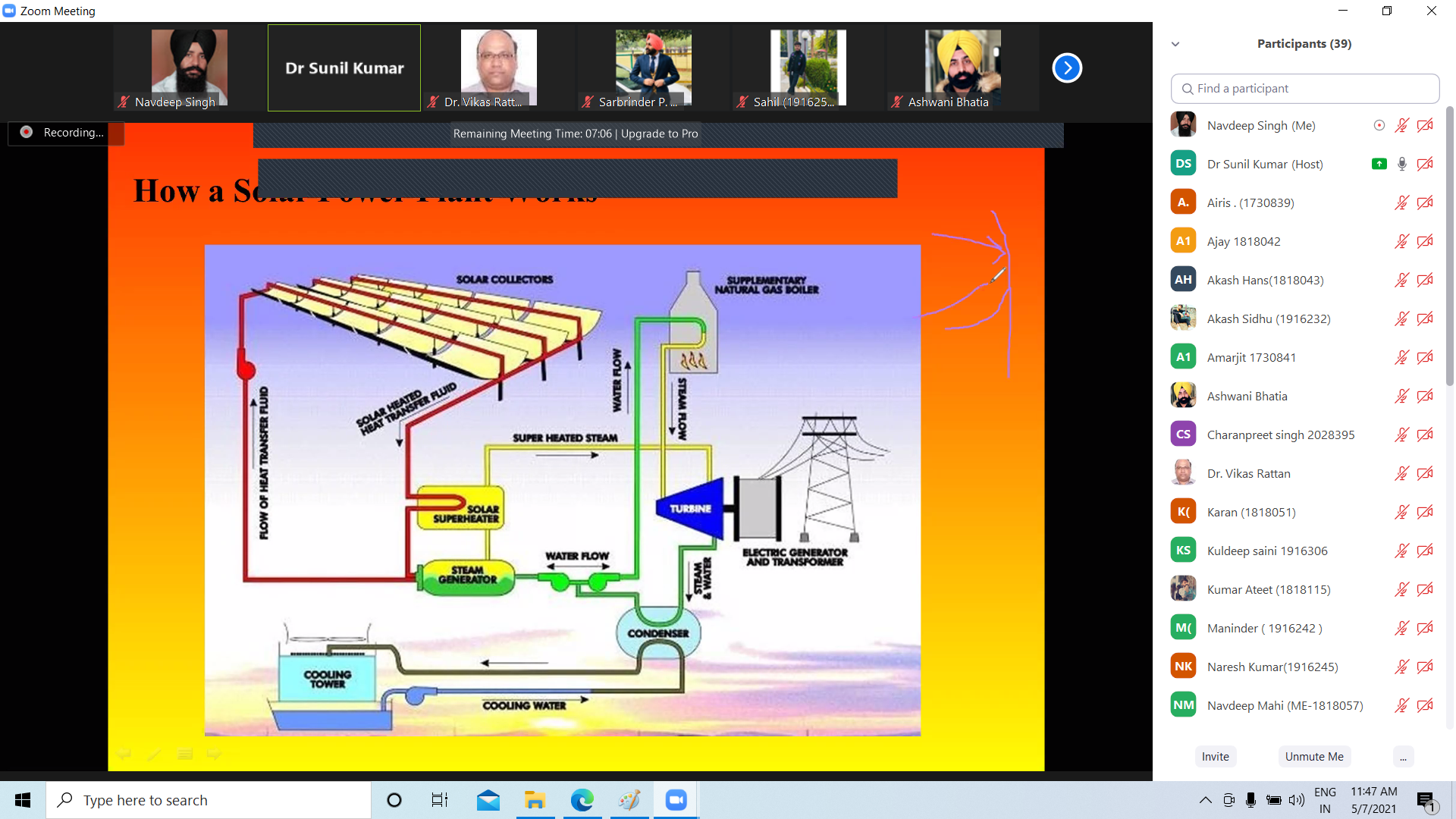

ALTERNATIVE ENERGY RESOURCES

An online Expert Talk was organized by Social Sensitization Committee of Department of Mechanical Engineering. The students of Mechanical 3rd , 5th and 7th semesters had participated in the session. Dr. Sunil Kumar Mahla (Assistant Professor, IKGPTU Campus, Hoshiarpur) shared deep information about “ALTERNATIVE ENERGY RESOURCES”. In their session, Doctor Mahla addressed the futuristic problems related to the Non- Renewable fuels (Coal, Petrol, Diesels etc) i.e. Scarcity, pollution and global warming caused by these fuels and emphasises to work on Renewable energy resources like Solar, Wind and Biomass energy resources. He also shared the information of renewable energy plants which had been installed in our country. He discussed that Punjab state is an agrarian state so it can reserve 48% energy potential to serve the nation from agro waste and animal waste. In this interactive session, students have shown their keen interest and clear their queries. Dr. Vikas Rattan (HOD, ME) presented vote of thanks for guest speaker. Er. Navdeep Singh, Assistant Prof. (ME), Er. Vishal sharma, Assistant Prof. (ME) coordinated the entire event. Prof. Sukhbir Singh Chatha, Director Academic Affairs KCL Group and Dr. R.S.Deol, Dy. Director AA KCL Group appreciated the efforts of the ME Department and motivate them to manage such types of activities in future also.

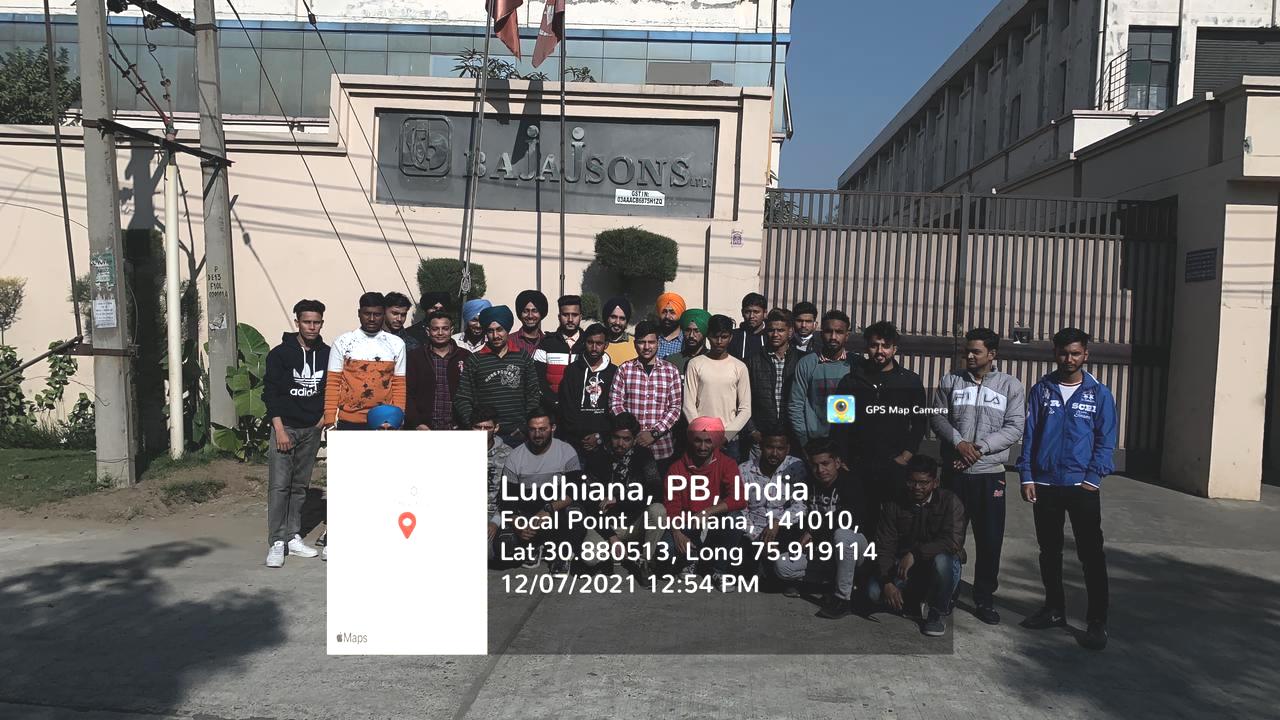

Industrial visit to Bajaj sons located at Ludhiana

Department of Mechanical Engineering in collaboration with Training and Placement department of LKCTC organised an industrial visit to Bajaj sons located at Ludhiana. The industry is well known for manufacturing of Auto parts especially Motorcycle parts. Students of ME 2nd and 3rd year were part of the visit. Students learnt about up-to-date industrial practices involving Automation. Students learnt the working of the automatic MIG welding, CNC’s and VMC machines along with the coding and various mechanisms involved for the smooth running of the WIP Inventory.

It was indeed a brilliant visit and students learnt much about the new technologies used in industry. S. Sukhbir Singh Chatha (Director, Academic Affairs, KCL Group) and Dr. R.S Deol (Deputy Director, Academic Affairs, KCL Group) appreciated the effort of the department and T&P cell by encouraging more of such visits in near future.

Volleyball Tournament

Mechanical Engineering Department, School of Engineering at LKCTC organized Volleyball Tournament 26-29th November 2021.Volleyball teams of various departments participated in the tournament with great enthusiasm. The tournament was proposed to enhance the overall development of students. The Final match was played between CSE and B.Voc teams. The CSE team grabbed the winner title making a 2-1 victory over the rivals.

The overall Coordinator of the event was Er. Aman Sharma (AP ME). Also the HOD, Mechanical Engineering (Dr. Vikas Rattan) welcomed the dignitaries and staff members to the final match. Director Academic Affairs, KCL Group, (Prof. S.S Chatha), Dy. Director Academic Affairs, KCL Group, (Dr. R.S Deol) and Director, LKCTC, (Dr. S.K Sood) made an interaction with the players and motivated students to participate in sports events alongwith study.

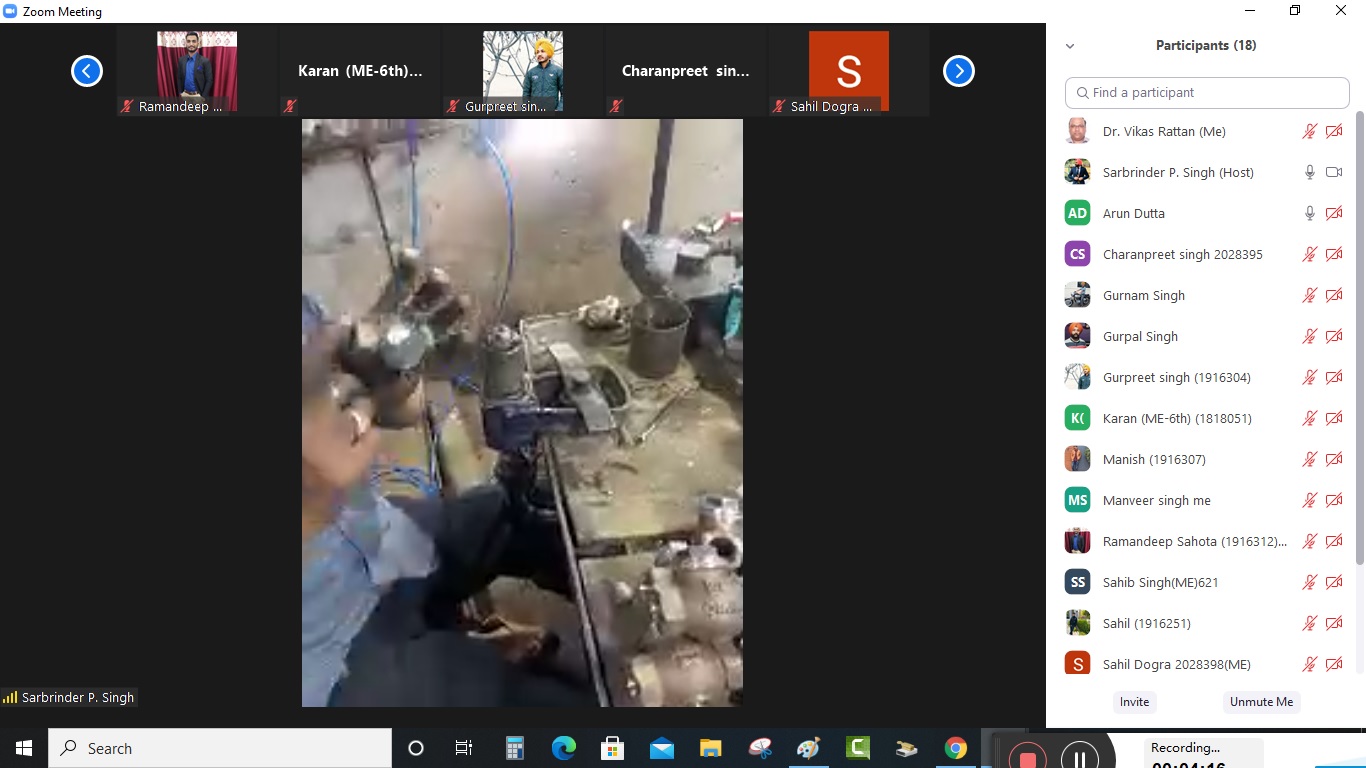

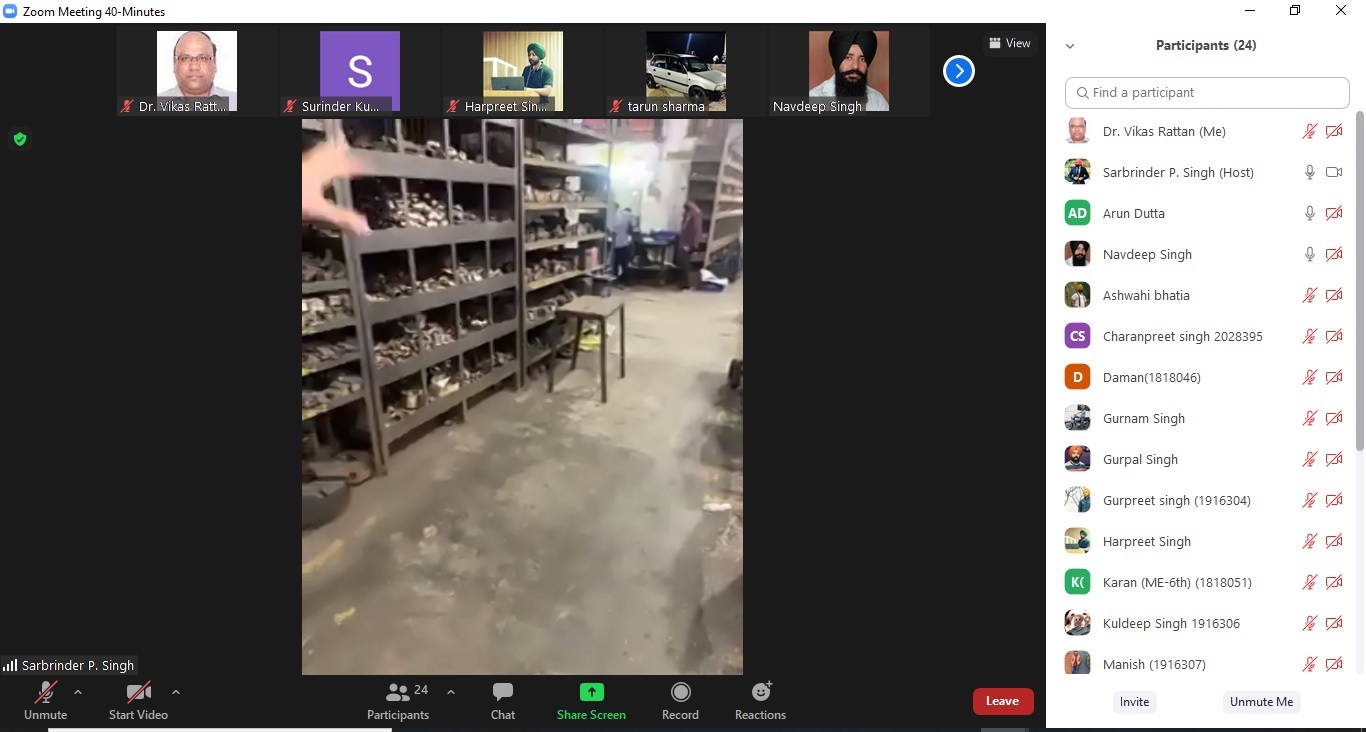

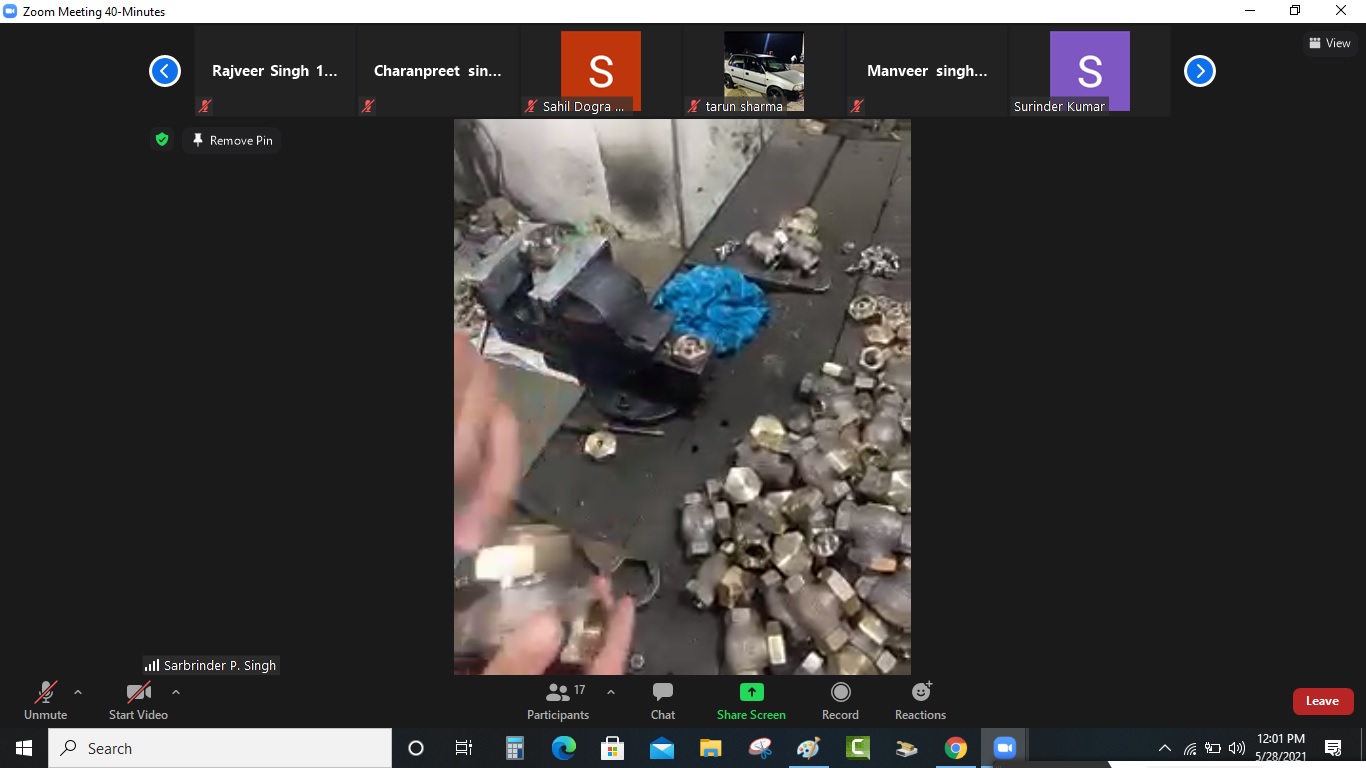

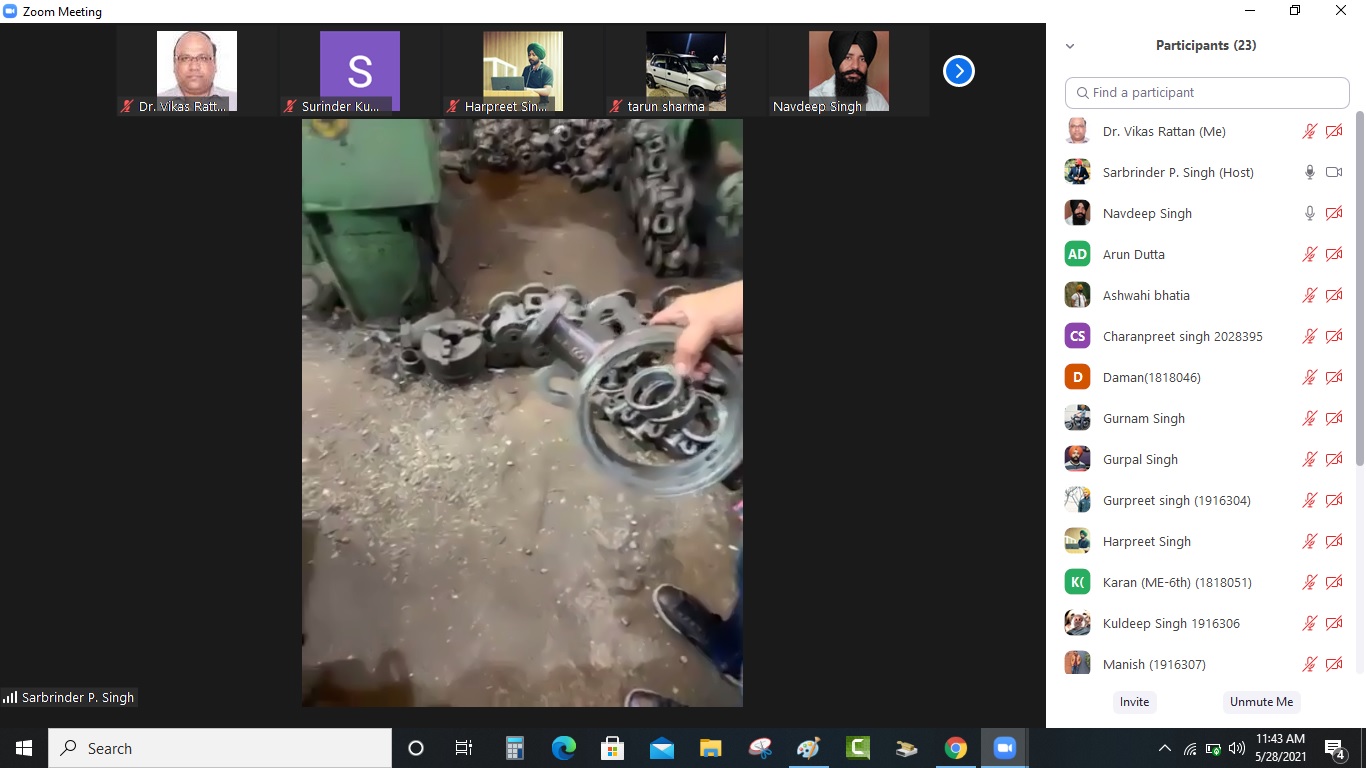

E-Industrial visit to Valvco International, Jalandhar on 28-05-2021

Department of Mechanical Engineering in collaboration with T&P Cell, LKCTC organized a

Virtual Industrial Visit to Valvco International, Jalandhar, a well known industry for

manufacturing of valves. The visit was done via video conferencing using Zoom app as a

platform. Students of all semesters of Mechanical Engg. department participated in the virtual

visit. The main focus of visit was on process planning which includes the various mechanical

processes such as Casting, shot blasting, grinding, Machining, Assembly and Testing.

Furthermore, students learnt about various materials used for the manufacturing of valves.

This visit indeed served as excellent source of practical knowledge for students.

The session was handled by Er. Shantanu (MD,Valvco International) and Er. Sarbrinder Pal

Singh (AP ME Department, LKCTC Jalandhar).

Prof. Sukhbir Singh Chatha, Director (Academic Affairs), LKCTC and Dr. R.S.Deol,

Dy.Director (Academic Affairs) LKCTC appreciated the efforts of ME department and T&P

cell for conducting such sessions to keep students updated with the current practices of

manufacturing and testing of products.

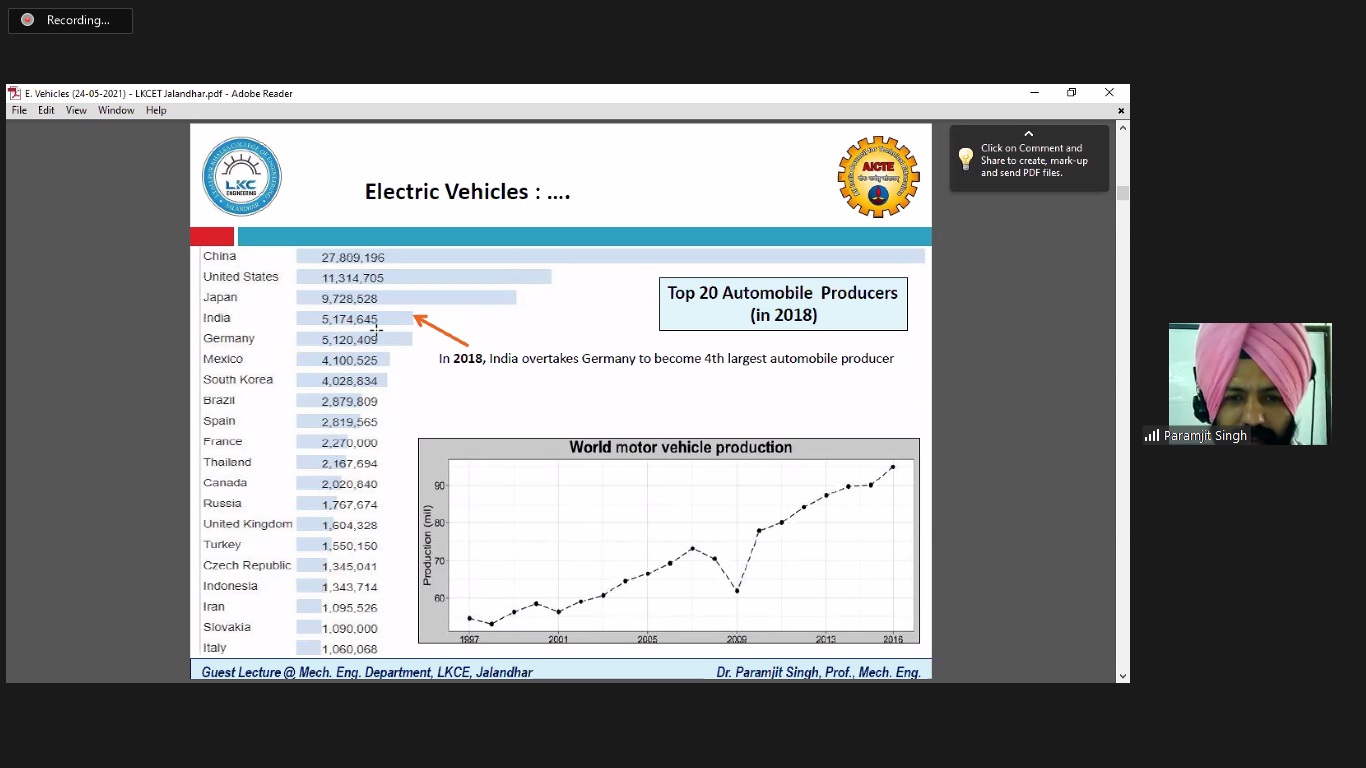

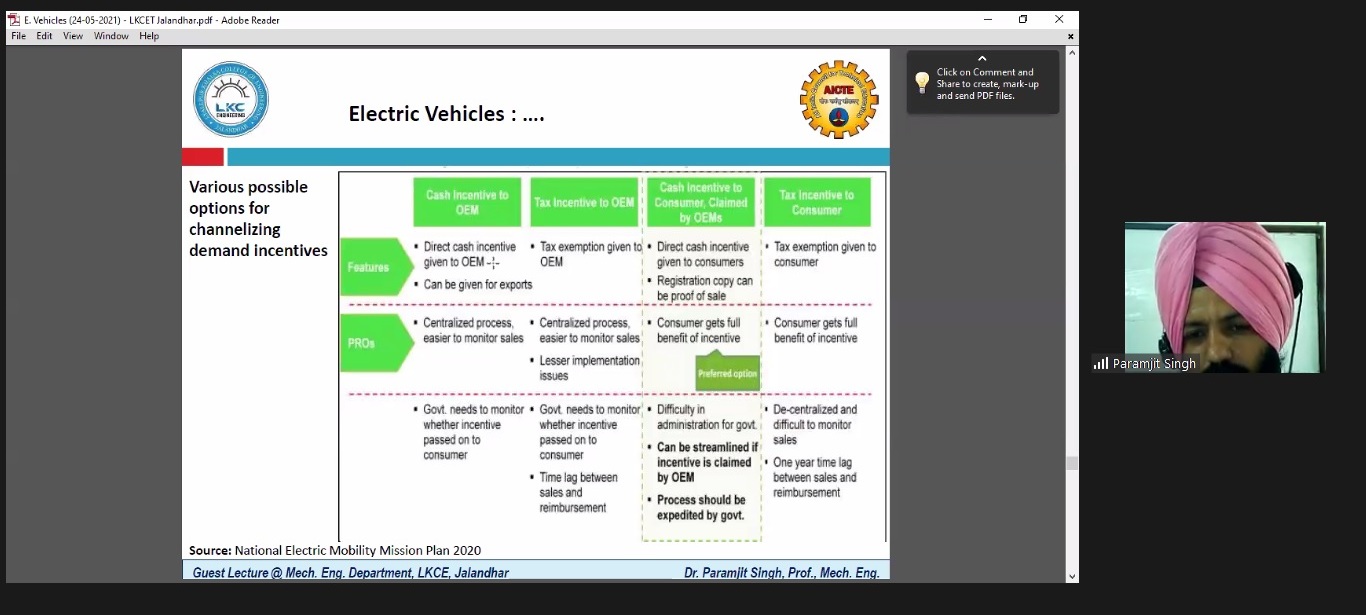

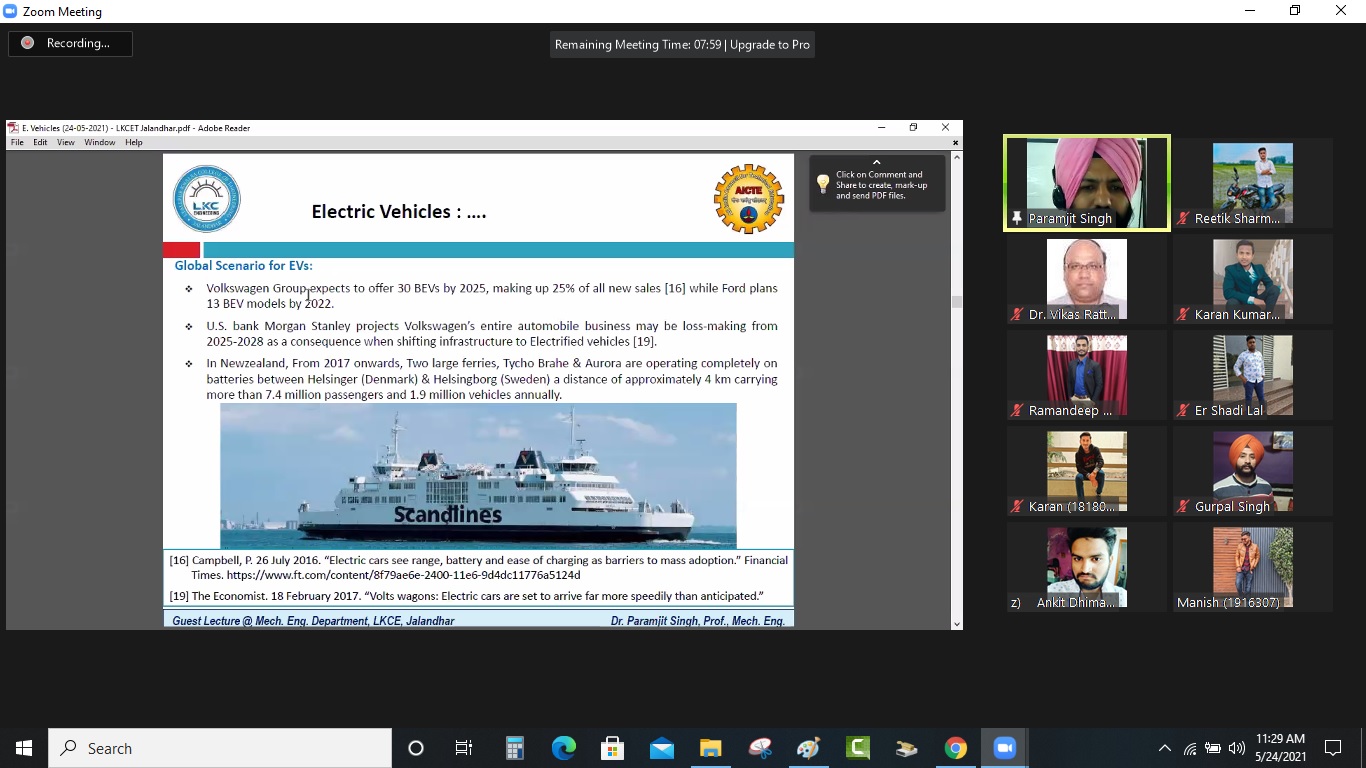

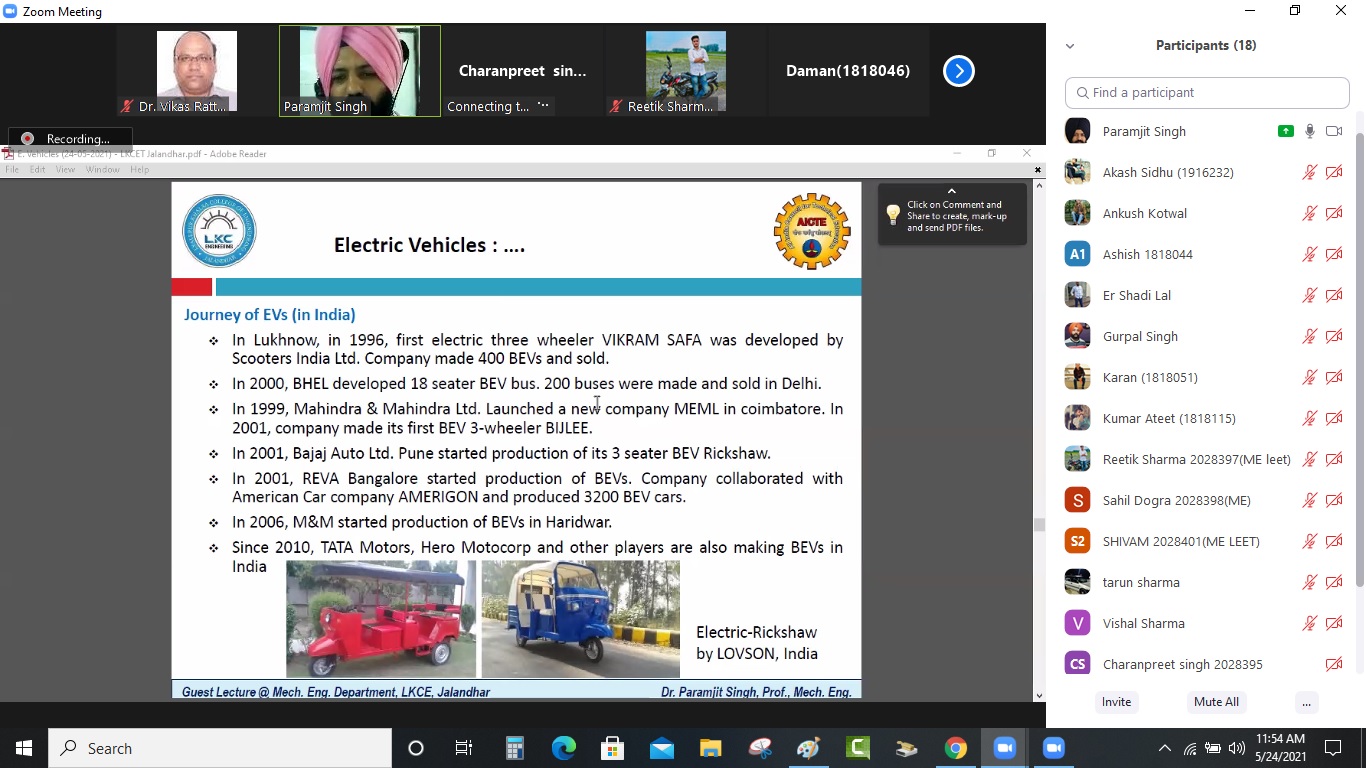

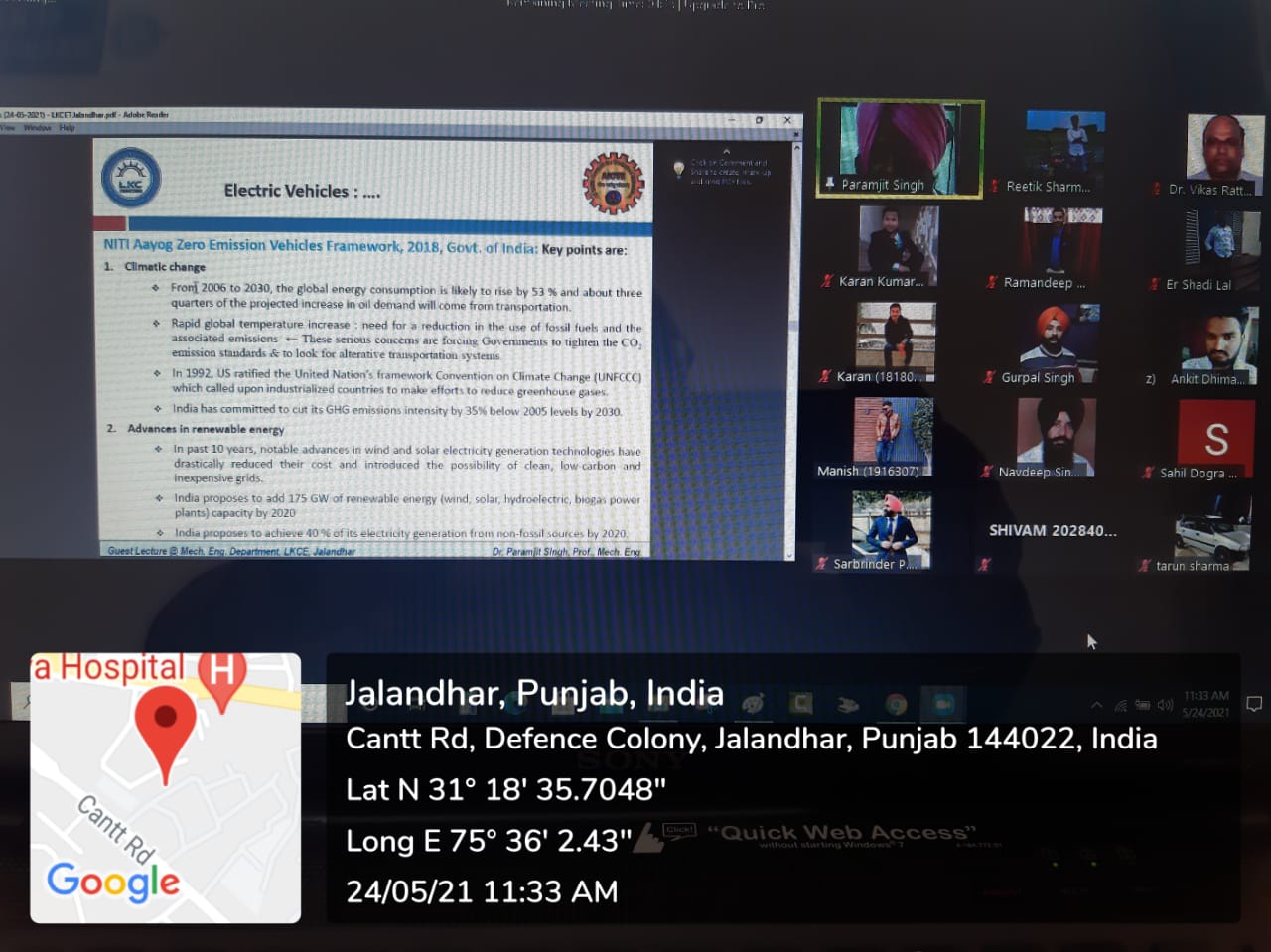

ONLINE EXPERT TALK ON "Electric Vehicles: Current status and future in India"

Department of Mechanical Engineering, LKCTC organized an online lecture on the Electric

Vehicles: Current status and future in India. The lecture was delivered by Dr. Paramjit

Singh Pannu, (Professor & Head, Deptt. of Mechanical Engg., Amritsar Group of Colleges,

Amritsar) on 24/05/2021. Dr. P.S. Pannu enlightens the students with his talk on the present

and future scenario of electric vehicles in India and also throughout the world. The session

was interactive and students participated with interest. Dr. Vikas Rattan, (HOD, ME)

coordinated the entire event. Prof. Sukhbir Singh Chatha, Director (Academic Affairs),

LKCTC and Dr. R.S.Deol, Dy.Director (Academic Affairs) LKCTC appreciated the efforts of

the department and motivate them to plan these types of activities in future also.

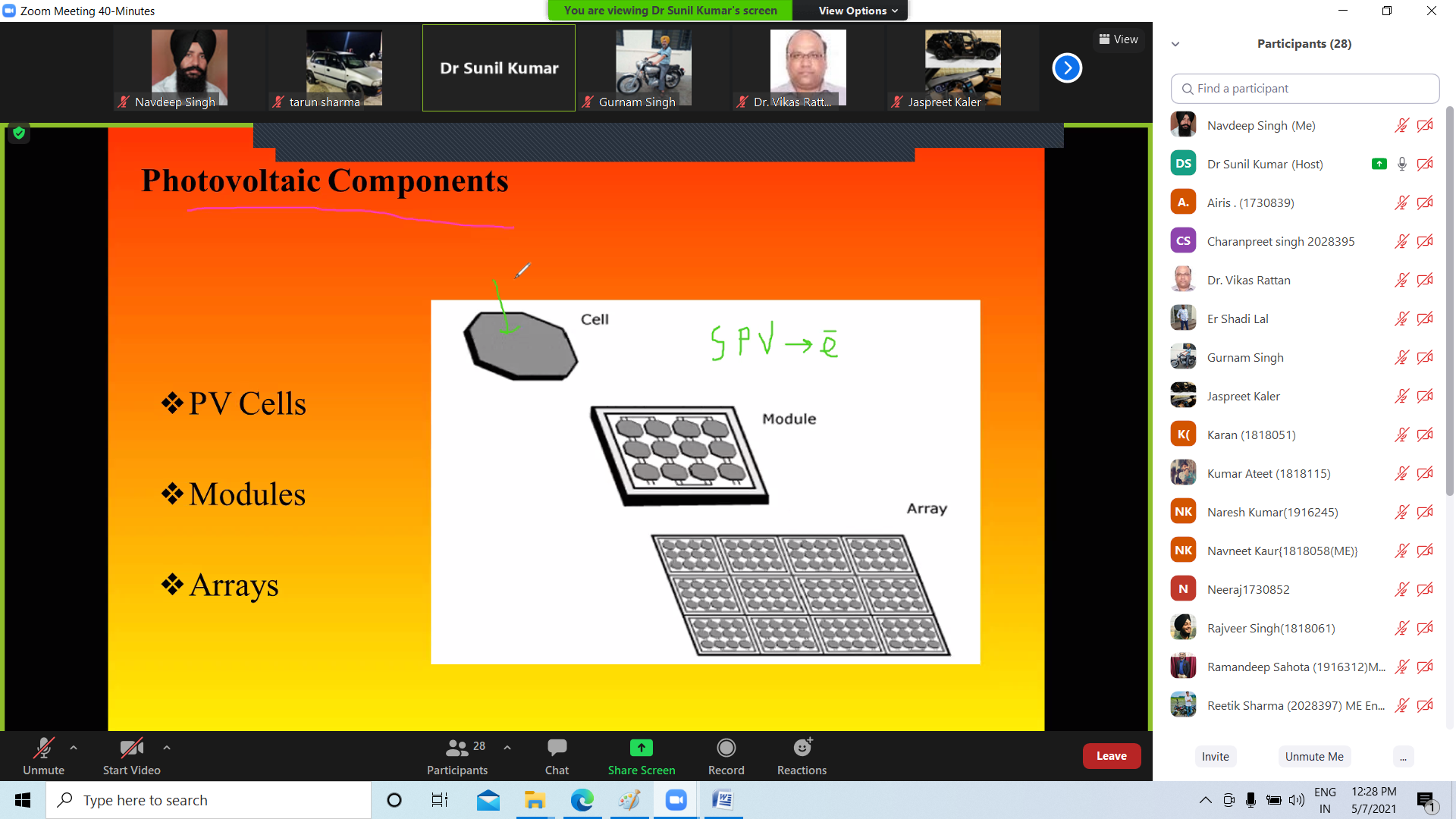

Expert talk on NON CONVENTIONAL ENERGY RESOURCES.

An online Expert Talk was organized by Social Sensitization Committee of Department of

Mechanical Engineering on 7th May 2021. The students of Mechanical 4 th , 6 th and 8th

semesters had participated in the talk. Dr. Sunil Kumar Mahla (Assistant Professor, IKGPTU

Campus, Hoshiarpur) delivered an expert talk on “NON CONVENTIONAL ENERGY

RESOURCESâ€. In their session, Doctor Mahla addressed the futuristic problems related to

the depletion of Non- Renewable fuels (Coal, Petrol, Diesels etc) and emphasises to work on

Renewable energy resources like Solar, Wind and Biomass energy resources. He has also

shared the information related to various renewable energy plants which are installed in our

country and other countries. In this interactive session, students have shown their keen

interest and clear their queries. Dr. Vikas Rattan (HOD,ME) presented vote of thanks for

guest speaker. Er. Navdeep Singh, Assistant Prof. (ME), Er. Gurnam singh, Assistant Prof.

(ME) and Er. Visahl Sharma, Assistant professor (ME) coordinated the entire event. Prof.

Sukhbir Singh Chatha, Director Academic Affairs KCL Group and Dr. R.S.Deol, Dy.

Director AA KCL Group appreciated the endeavours of the ME Department and motivate

them to arrange these types of activities in future also.

Alumni Interaction of students

Department of Mechanical Engineering of LKCTC organized an Alumni Talk on 04-05-2021, where one of the proud Alumni of LKCTC ME Deptt. Er. Harmanpreet Singh

(Executive Head, Chinar Forgings, Jalandhar) delivered an interactive session using Zoom platform with current students

of Mechanical Engineering of 4th, 6th and 8th semester on “Scope of jobs after B Tech. ME.

The main focus of the interaction was on skill set building and to enhance the inherited attributes.

Further, in order to enhance the skills

Er. Harmanpreet Singh shared valuable online resources which can be easily accessed by the students.

The overall coordinator of the event was Er. Sarbrinder Pal Singh. HOD ME welcomed our Alumni.

Director Academic Affairs, KCL Group, (Prof. SS Chatha), Dy. Director Academic Affairs, KCL Group, (Dr. R.S Deol)

appreciated the effort of ME Department and Er. Harmanpreet Singh for sharing his wisdom with current

under graduates of Mechanical Engineering.

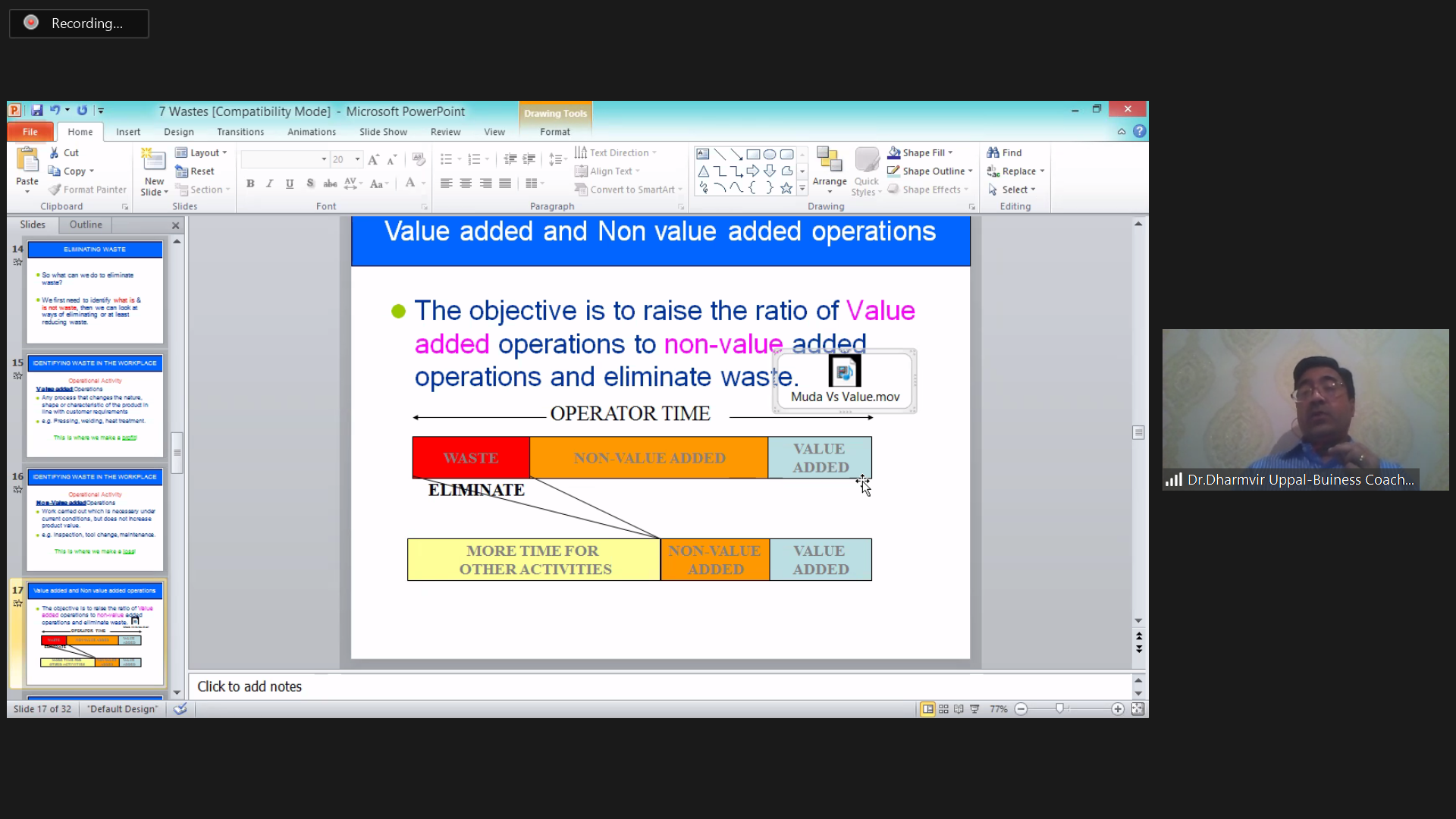

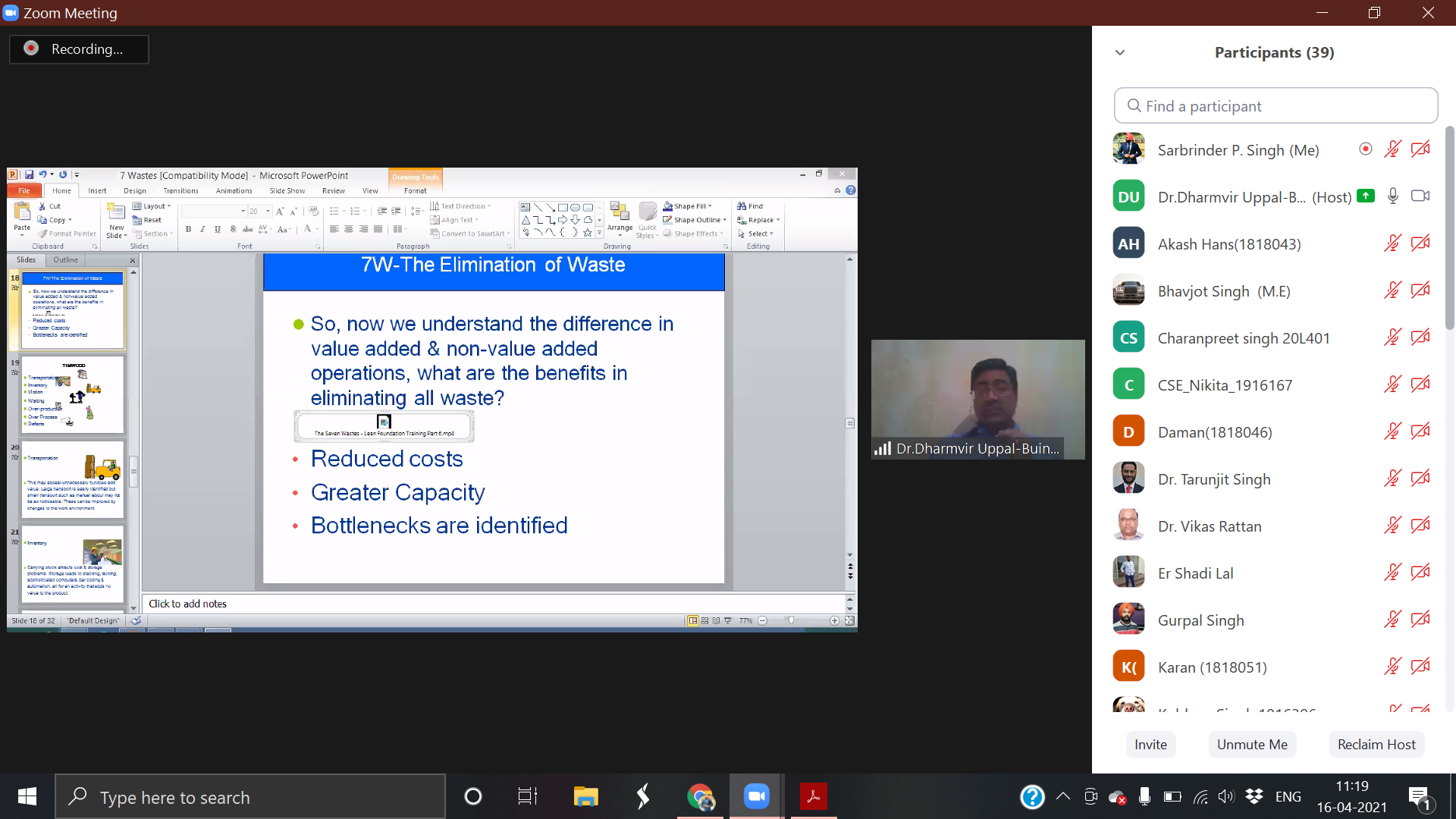

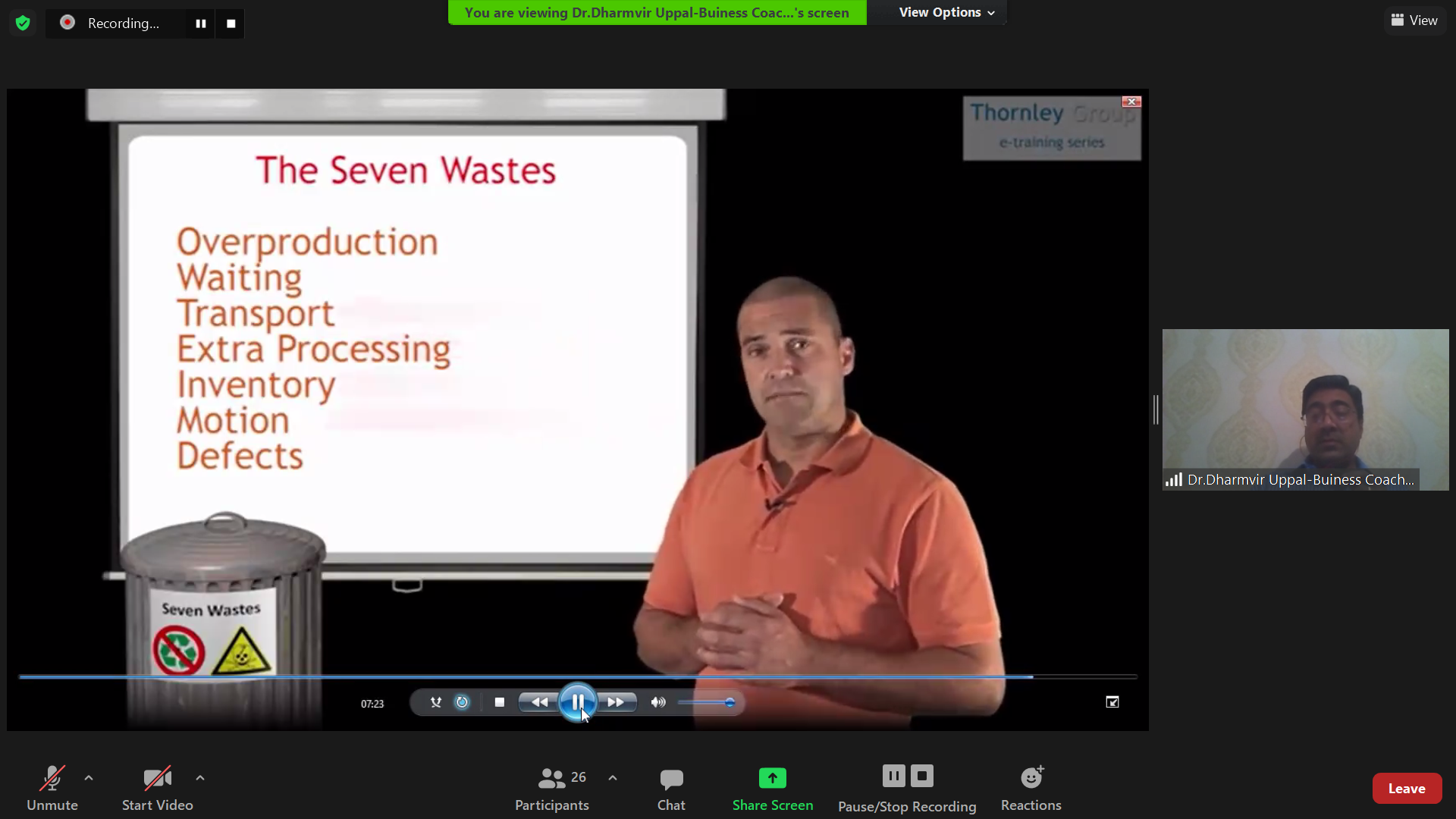

ONLINE WORKSHOP ON LEAN MANUFACTURING

Department of Mechanical Engineering in association with T&P Cell, LKCTC organized an

online lecture on the 7 deadly lean wastes (TIMWOOD)- Destroying your profits in

Manufacturing. The lecture was delivered by Dr. Dharmvir Uppal Ph.D. in Lean

Manufacturing (Business Coach and Certified Master NLP) on 16/04/2021. Students from all

the departments participated in the event with a strong zeal acquainting them of types of

losses in industries, hospitals and malls which adds no value to the customer but adds

overheads to the industry and other organizations. The overall coordinator for the event was

Er. Sarbrinder pal singh and HOD ME (Dr. Vikas Rattan) welcomed Dr. Dhramvir Uppal.

Prof. Sukhbir Singh Chatha, Director (Academic Affairs),KCL Group, LKCTC and Dr.

R.S.Deol, Dy.Director (Academic Affairs ), KCL Group, LKCTC appreciated the efforts of

T&P cell LKCTC and ME department for organizing such event which leads to informing

students about world class manufacturing.

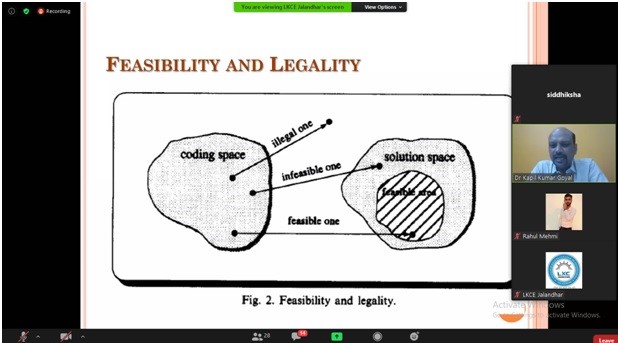

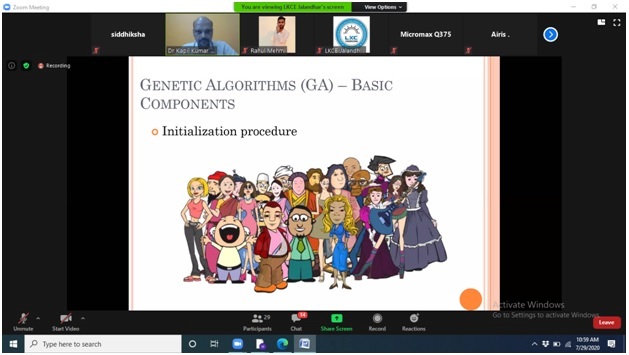

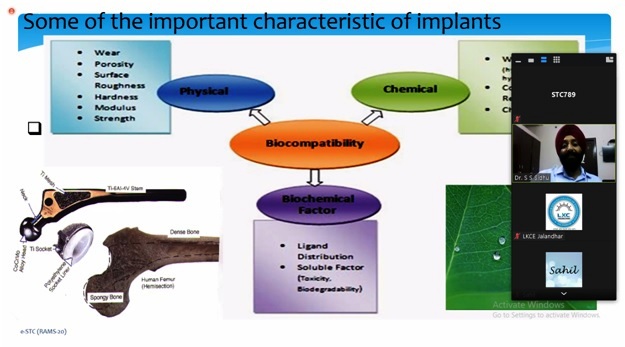

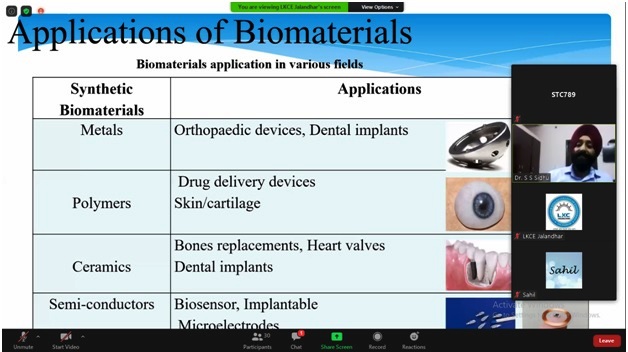

Online short term course on Recent Advances in Mechanical Engineering Systems

The Department of Mechanical Engineering of Lyallpur Khalsa College of Engineering on July 29th-31st July, 2020 had organized a 3 Days E-STC on Recent Advances in Mechanical Engineering Systems for the students of mechanical engineering.

To provide students a technical edge in industry oriented programs and to help them perform well during technical rounds of campus placement, Department of Mechanical Engineering, LKCE Jalandhar organized a free online short term course on Recent Advances in Mechanical Engineering systems. The resource persons, Dr. Kapil Kumar Goyal (AP NIT Jalandhar),Dr. Sarabjit Singh(Associate Professor BCET Gurdaspur),Dr. Gurraj Singh(AP NIT Jalandhar), Dr. Charanjit Singh (Modern Manufacturers Pvt. LTD), Dr. Neeraj Sharma(Post Doc, South Africa) and Dr. Vikas Rattan (Associate professor LKCE) taught students out of box Mechanical Engineering practices and many more advanced concept which are used in manufacturing industries.

A large number of students and faculty members attended the workshop. The resource persons provided emphasis on modern technology used for machining of Inconel and Titanium alloys. The latest being, advancements in 3D Printing and materials used in Bio-medical applications providing the information about expanded horizon of Mechanical Engineering even in the field of agriculture to curb phantom associated with paddy burning.

The inaugural speech was conveyed by Dr.D S Rao, Director LKCE and welcome speech was delivered by Dr. Satish Ragit (HOD ME). The vote of thanks was orated by Er. Aman Sharma. Furthermore, the session was handled by Er. Aman Sharma, Er. Navdeep Singh and Er.Sarbrinder pal Singh.

On successful completion of the online course, Mr. Sukhbir Singh Chatha, Director AA, Dr. R.S Deol, Dy. Director AA of LKCTC appreciated the efforts of Mechanical Engineering departments for coordinating such events and highlighted the significance of online short term courses on manufacturing practices and standard in industry. They further emphasized that such technical events will definitely help the students in achieving exceptional campus placement and higher studies at abroad or here in India. Furthermore, they motivated the department to take such initiatives in the near future.

Webinar on fundamentals of mechanical vibration

The Department of Mechanical Engineering of Lyallpur Khalsa College of engineering on July 2, 2020 had organized a webinar for the students of mechanical engineering. To acquaint students with the concept of mechanical vibration: which is a prerequisite for any mechanical engineer. The webinar inculcate the principles of damped, undamped and forced vibrations in machines along with methods of measurement of vibrations.

Keeping in view the current circumstances owing to covid-19, the lecture was delivered via zoom meeting and students from all semester of mechanical engineering department participated in the extension lecture. Orator for the session was Dr. SimranjeetSingh (Associate Professor, Pandit Deendayal Petroleum University, Gandhinagar, Gujarat). The event coordinators who managed the webinar promptly were Dr. Satish Ragit (HOD, ME) and Er. Sarbrinder P. Singh, Assistant Professor, M E Department.

Dr. R S Deol (Dy. Director AA KCL Group), Dr. D S Rao (Director, LKCE) appreciated the effort for organizing such informative lecture on for the young mechanical engineers. Furthermore, they motivated the department to take such initiatives in the near future.

INTELLECTICA ONLINE COMPETITION

Due to COVID-19 pandemic, Following the social distancing guidelines, under the guidance of LKCE management, Department of Mechanical Engineering had Organised an INTELLECTICA ONLINE COMPETITION on PICTURE PERCEPTION & DISCRIPITION and MENTAL ABILITY dated 08-06-2020 to keep the students in-touch with their study. In this contest, all outsider and regular students having minimum age 15 years were allowed to register themselves and students had shown their keen interest in registration and participation as well. The result was declared online on 09-06-2020 and E-Certificates were handed-over to all the Er. Aman Sharma and Er, Sarbrinderpal Singh coordinated this event and the other faculty members contributed well to make this event successful.

In the end, Dr. RS Deol (Dy. Dir. AA KCL Group), Dr. DS Rao ( Dir. LKCE) and Dr SS Ragit (HOD,ME), appreciate the efforts of all the students and motivate them to participate in such types of contests to update themselves. Also, advised to stay home and stay safe at this time of COVID-19 pandemic.

Picture Perception and Description Test

| Sr. No |

Student Name |

Class |

Semester |

Position Hold |

| 1. |

Nishant |

ME |

6th |

First |

| 2. |

Vanita |

CAD |

CAD |

First |

| 3. |

Anmol Rattan Singh |

CE |

6th |

second |

| 4. |

Nishant Kumar |

ECE |

8th |

Third |

| 5. |

Ritika Guleria |

CAD |

CAD |

Third |

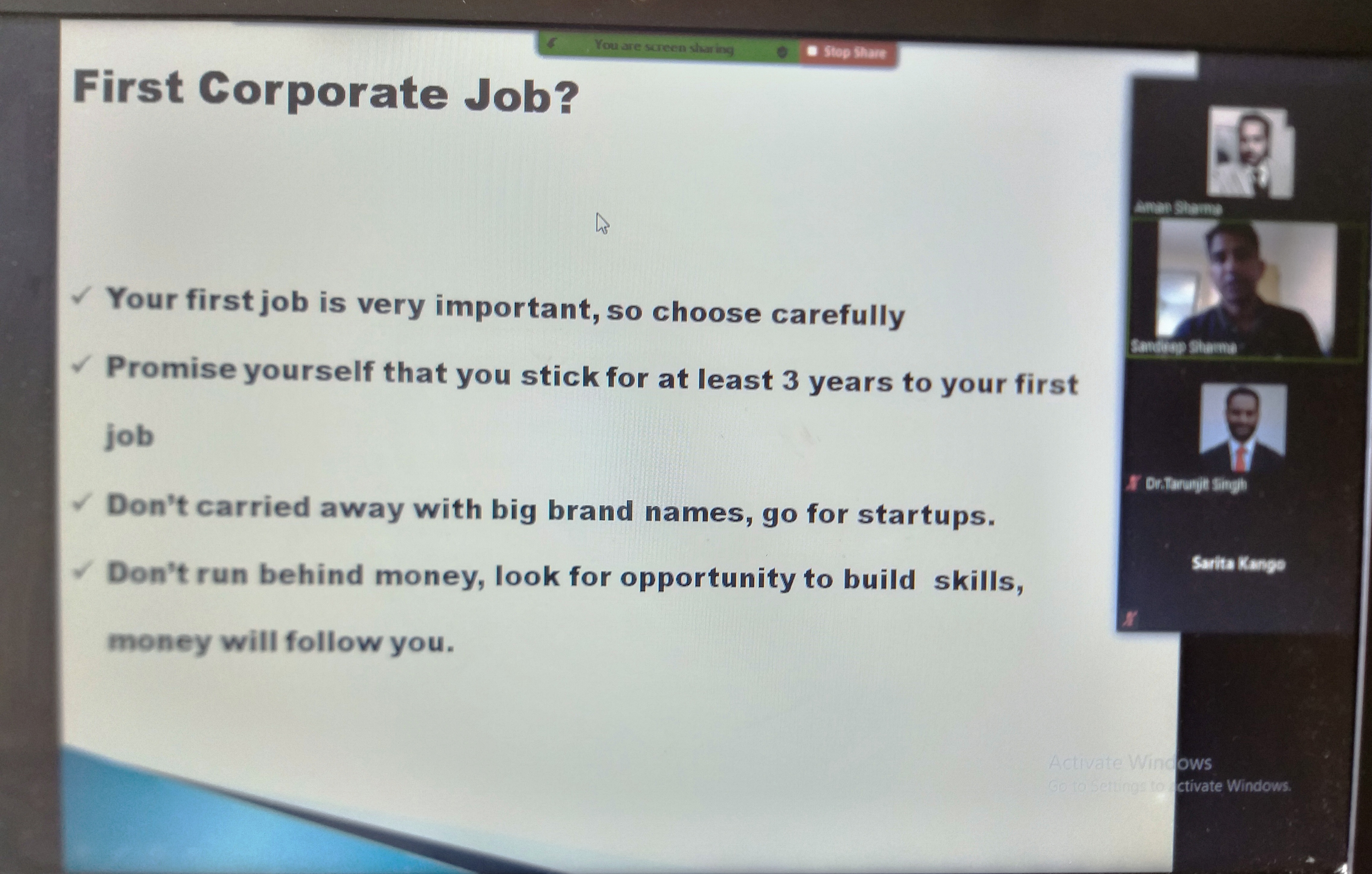

Online International webinar on Campus to Corporate

The Mechanical Engineering department of LKCE took the initiative to coordinate an online International webinar on "Campus to Corporate". These webinars extend and improve the student's view for career prospects and also make students aware of the future technological changes required due to the impact of the Covid19 pandemic. This webinar was conducted by Mr. Sandeep Sharma(Vice President, Corporate Affairs, J.P Morgan, Scotland, Uk) and organised by Er. Aman Sharma(A.P, ME Deptt., LKCE) ,where more than 60 students and faculty members participated. He encouraged the students to build up various personality skills which can make them placed in Multi National Companies. He also guided the students to learn in positive manner in these difficult times of Covid19 pandemic. S. Sukhbir Singh Chattha (Director Academic Affairs) encouraged the students for participation in such workshops and appreciated the Mechanical Engineering Department for organizing such events. Dr. R.S. Deol (Dy. Director, (AA) KCL Group) highlighted the importance of webinar and said it is very good to make interaction of students with corporate persons through such platforms. Dr. D.S. Rao (Director, LKCE) and Dr. Satish Ragit (HOD ME) also motivated the students and congratulated faculty members in the successful completion of this event.

Online Guest Lecture

Due to COVID-19 pandemic, Following the social distancing guidelines, under the guidance of LKCE management, Department of Mechanical Engineering had Organised an ONLINE GUEST TALK on Topic of THEORY OF FAILURES dated 13-05-2020 on ZOOM MEETING App. Dr. Harish Garg, Associate Professor in DAV University, host this expert lecture and students of ME 4th and ME 6th participated in this online event. Dr. Garg made this session very attractive by giving the practical examples relevant to the title of this session and also students had shown their deep interest by arising their queries. In this session, Host discussed different kinds of failures of materials on the basis of different theories. Er. Navdeep Singh and Er. Aman Sharma had coordinated this event. In the end, Dr SS Ragit (HOD,ME), Dr. RS Deol (Dy. Dir. AA KCL Group), Dr. DS Rao ( Dir. LKCE) motivate the students to use E-Resources to the utmost to update their knowledge and advised to stay home and stay safe at this time of COVID-19 pandemic.

ONLINE GUEST TALK

Due to COVID-19 pandemic, Following the social distancing guidelines, under the guidance of LKCE management, Department of Mechanical Engineering had Organised an ONLINE GUEST TALK on Topic of 'ECHO FRIENDLY COOLING SOLUTIONS FOR INDIA: AN APPLICATION BASED STUDYdated 22-05-2020 on ZOOM MEETING App. Dr. Simarpreet Singh Director, Reftech Pvt. Ltd. & PDF from NTNU, Norway host this expert lecture and students of ME 4th and ME 6th participated in this online event. Dr. Simarpreet Singh made this session very attractive by giving the practical examples relevant to the title of this session and also students had shown their deep interest by arising their queries. In this session,Host discussed bad effects of synthetic based refrigerants on environment and human healt and benefits of natural refrigerants those are eco friendly. According to Mr. Singh India is a signatory to both COP21 which was ratified on 2nd October 2016 and Kigali agreement of 2017. Both these protocols make India to mitigate the problems arising from greenhouse gasses, especially used for refrigerants. The various area of application of the CO2 system are data centre cooling, simultaneous heating and cooling, supermarket cooling, air conditioning and so on. The proposed technology, being based on CO2 refrigerant (natural substance) and its use are not only environment friendly but also safe to user.

In addition, the CO2 refrigeration is also efficient, thanks to the technology advancement. Ejector technology significantly improves the overall efficiency by reducing the power input ratio of the system even at high ambient climate context. Therefore, in the long run, the matured CO2 technology would be beneficial and attractive from both environment and energy points of view. Er. Harmanpreet Singh and Er. Navdeep Singh had coordinated this event.<

In the end, Dr S S Ragit (HOD,ME), Dr. RS Deol (Dy. Dir. AA KCL Group), Dr. DS Rao ( Dir. LKCE) motivate the students to use E-Resources to the utmost to update their knowledge and advised to stay home and stay safe at this time of COVID-19 pandemic.

Expert Talk

An Expert Talk was organized by Social Sensitization Committee, Department of Mechanical Engineering on 06-Feb-2020. The faculty and the students of 4th and 6th semesters of Mechanical Department participated in this event. Dr. Sunil Kumar Mahla (Assistant Professor, IKGPTU Campus,Hoshiarpur) delivered his lecture on Application of Applied Thermodynamics in Renewable Energy Resources. Dr DS Rao (Director LKCE.), Dr SS Ragit (HOD ME), Er. Gurnam Singh along-with other Faculty Members of Mechanical Department gave the floral welcome to Dr. Sunil Kumar Mahla. The basics of Thermodynamics and benefits of renewable energy resources in our daily life were deeply discussed by Dr, Mahla. Also, Speaker enlightens the emerging issues of health hazard by stubble burning and discussed the various methods to curb it. He also motivated the students to work hard in their Technical Field and do research in the field of renewable energy resources which may work for society welfare. In this interactive session students participated with full interest and clear their doubts about the subject through their queries.Er. Gurnam singh, Assistant Prof. (ME) and Er. Navdeep Singh, Assistant Prof. (ME) coordinated the entire event. In the end, Prof. Sukhbir Singh Chatha (Director Academic Affairs), Dr. R.S.Deol (Dy. Director KCL Group) and Dr,DS Rao (Director LKCE) appreciated the endeavours of the department and motivated to arrange these types of activities in future also.

Guest lecture by Dr. Harpreet Singh Grewal

On 07th October 2016, Dr. Harpreet Singh Grewal, Assistant Professor, Deptt. of Mechanical Engg., Shiv Nadar University, Greater Noida, delivered a guest lecture on the topic "Importance of Tribology in Mechanical Engg.". Dr. Grewal discussed his research work in the field of Tribology. Faculty and under-graduate students of Mechanical Engg., Deptt., gained knowledge from Dr. Grewal's vast experience. Dr. Sukhraj Singh, HOD Mechanical Engg., Deptt., said that to keep technically update the Faculty and Students, these types of expert lectures are conducted timely in deptt.

Dr. Y. S. Randhawa, Director, LKCE congratulated the deptt. for this effort.

Training and Placement drive

Mechanical department students on Training and Placement drive Majestic auto ltd. At Guru Nanak Dev Engineering College, Ludhiana.

Educational Industrial visit at GNA Duraparts, Mehtiana

On 6th November 2015, Department of Mechanical Engineering organized an industrial visit of the Fifth semester Mechanical Engineering students to GNA Duraparts Mehtiana. The purpose of visit was to enhance the practical technical skills related to the latest CNC technology used in manufacturing industry. Advanced CAM technology was practically explained by the experts of GNA Duraparts. Er. Gagandeep Singh and Er. Navdeep Singh accompanied the students and guided them about the future prospects of Mechanical Engineering. Dr. Sukhraj Singh, HOD Department of Mechanical Engineering said these types of visits are necessary to aware the students about the latest technology being used by industry.

Guest lecture by Dr. Jagdev Singh

On 18th September 2015, Dr. Jagdev Singh, Associate Professor, Beant College of Engineering and Technology, Gurdaspur, delivered a guest lecture on the topic "Applied Thermodynamics — Need of Thermodynamics Processes" and cleared the air for the students who were enlightened on various topics of Applied Thermodynamics. The need of basic processes was opened up in detail as per their applications. The aim of the lecture was to make the students capable of interpreting the primary terms which Applied Thermodynamics incorporates. The topics which we discussed vividly were- Different approach to basic topics and Practical applications of Applied Thermodynamics.

The enthusiasm and the interest with which the things were unveiled was one experience to cherish for long time to come for both the students as well as the faculty.

Guest lecture by Dr. Jagdev Singh

On 15th September, 2015, the Department of Mechanical Engineering, Lyallpur Khalsa College of Engineering celebrated Engineer's Day to commemorate the 155th birthday of Bharat Ratna Sir Mokshagundam Visvesvaraya, an Indian engineer, scholar, statesman and the Diwan of Mysore from 1912 to 1918. He was the chief designer of the flood protection system for the city of Hyderabad in Telangana, as well as the chief engineer responsible for the construction of the Krishna Raja Sagara dam in Mysore.

On this occasion Mr S.S. Chatha (Director Academic Affairs), Dr. Y.S. Randhawa (Director LKCE) congratulated and awarded the winners Simmerjit Singh (Turbo Debate), Ankit Suman(Classic Workshop) and Shubham Khanna (Mind's Eye Drawing) and appreciated the efforts of the department. Dr. Sukhraj Singh (HOD-ME Deptt.) along with the other faculty members concluded the function by encouraging the students for active participation and progress of the institute.

Celebrating Teachers Day

Teachers day was celebrated in the Department of Mechanical Engineering, Lyallpur Khalsa College of Engineering to remember and regard Dr. Sarvepalli Radhakrishnan. Dr. Sukhraj Singh, HOD, ME, adrreses the students about the importance of the day, about contributions of Dr. Sarvepalli Radhakrishnan to Indian society. He also motivates the students to waor hard in studies and to respect & remember their teachers. Students also shared their views on the day's importance.

Inauguration of new building pics